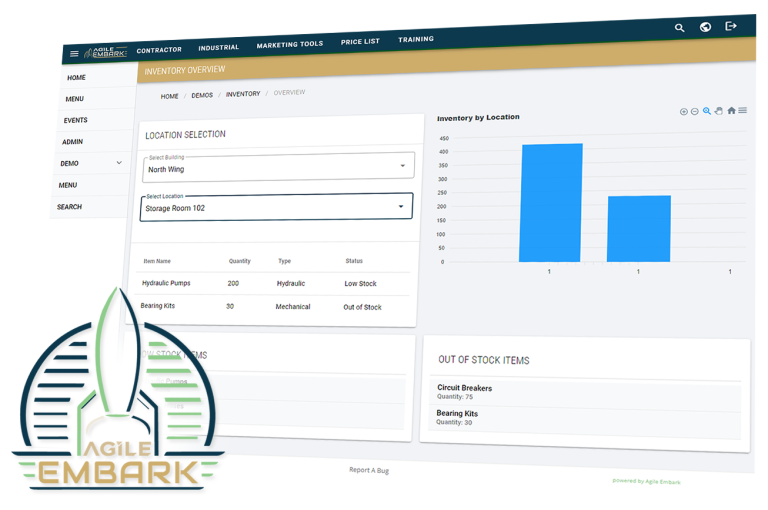

In this example, Agile Embark is used to meet specific inventory management and tracking needs for a large manufacturer selling online.

A manufacturing plant with an extremely large amount of product types was facing inventory struggles. Many product types have very specific storage needs, therefore making it hard to manage efficiently bases on physical storage, routing, and rapidly fluctuating levels.

Inventory management is often a challenging task for industry-standard use cases. In this case, specific items require unique storage properties, locations, and meticulous management. This complexity ruled out virtually all available inventory applications.

Additionally, the nature of their business model causes inventory to change rapidly and frequently. This constant fluctuation demands an accurate and versatile solution to enable proper tracking, reporting, and movement.

Compounding these issues are the requirements for real-time data visibility and seamless integration with other business processes. The lack of a robust system results in inefficiencies, increased errors, and significant time spent on manual adjustments and audits. This environment necessitates a highly adaptable inventory management approach to keep pace with the dynamic nature of the business.

Agile Embark was utilized to create a management system tailored to handle complex inventory logistics with specific needs. The flexibility of our platform allowed the client to convey their current methods to our consultants, who then designed a digital replica of their existing system.

Our consultants identified key areas for implementing custom automation and reducing user input. This enabled the client to manage their inventory precisely as required. Additionally, our dedicated development team ensured seamless integration of the new data with multiple third-party systems.

This client quickly took advantage of the flexible modularity of Agile Embark. We followed our standard iterative process, rapidly producing working prototypes of the required items for review and refinement. This approach significantly shortened the time from concept to production.

Additionally, our consultants identified areas for improvement, which encouraged the client to become even more involved in the development process. Once they realized the power and potential of Agile Embark, the project evolved from merely replicating their existing processes to over a year of ongoing alterations and improvements.

Their growing understanding of the Agile Embark platform allowed them to continually assess their current processes and make necessary adjustments. This resulted in a collaborative partnership that continues to thrive today.

The client has consistently relied on Agile Embark to replace third-party systems that didn’t fully meet their needs. As a result, a significant portion of their operations is now managed using the Agile Embark platform.

Discover how Agile Embark has transformed businesses across various industries. Explore our case studies to see real-world examples of how our flexible platform has streamlined operations, enhanced efficiency, and provided powerful data insights. Learn from the success stories of our clients and see how Agile Embark can drive innovation and growth for your business.

Discover the power of a platform that is as adaptive as your business needs.

With Agile Embark, embrace the potential of a system that offers everything from simple solutions to full-scale ERP integrations, all while presenting the face of your brand.

Join us and transform your business operations with technology that is powerful, adaptable, and uniquely yours.

We will contact you shortly